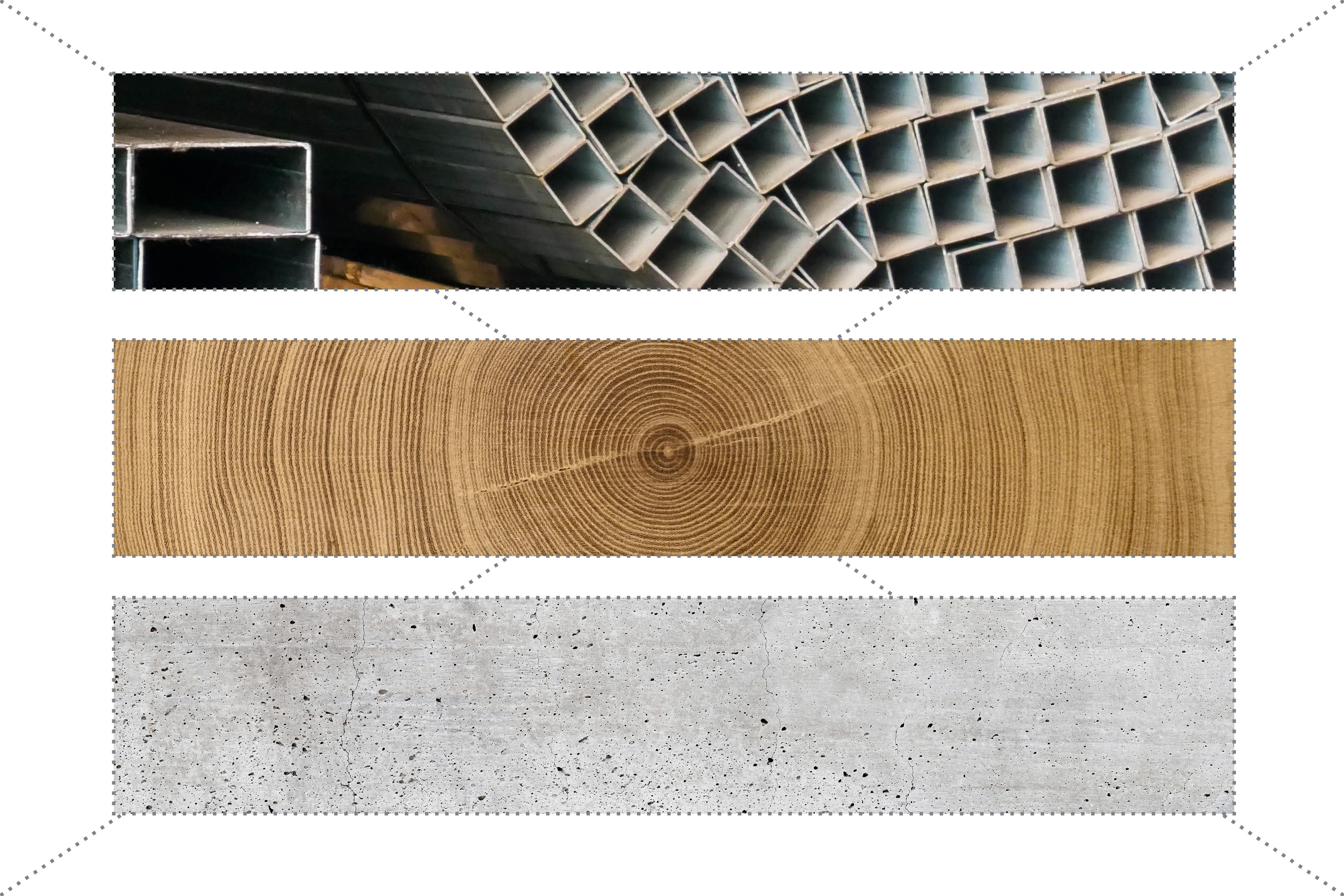

Wood is an integral part of the construction. It is a flexible building material since it can be obtained almost anywhere. Since it was more effective than carrying other materials all the way from Europe, early immigrants in North America utilized wood to construct log huts. Wood doesn’t need the usage of complex equipment in order to be manufactured as a building material (Rosmanitz, 2013). Wood was perhaps the most reliable construction material available, long ago. Because wood is so reliable, houses constructed over 800 years ago are still holding strong (Hoibo, Hansen, & Nybakk, 2015). Looking back in time, wood is still the favored method for building houses even now. After wood, concrete was the new material invented, and has been utilized in numerous ancient civilizations, notably Rome and Egypt, when resources were few and wood could not be procured. Concrete is commonly utilized nowadays in basements, bridges, and big industrial structures as it is one of the most resistant and affordable materials available.

Taking a glance around, it is possible to claim that the most widely utilized building materials in construction nowadays are concrete and steel. Concrete, on the other hand, is produced in an unsustainable manner, as opposed to wood. Concrete cannot be recovered and is left where it is demolished, but timber can be torn down and reused. Steel is the most recently developed of the three materials. Steel’s sturdiness made it a popular construction material throughout industrialization. Throughout this time, most individuals progressively transitioned from wood to steel construction. Talking about the current era, we know that wood is the finest alternative for long-term sustainability. The evolution of concrete and steel may not be the most Eco-friendly approach.

Despite the overwhelming challenges posed by global climatic changes, sustainable construction is the only option for the building industry to contribute to a more sustainable and healthier future. Briefly expressed, sustainability implies constructing to fulfill the requirements of the current era without jeopardising future generations’ potential to cope using its own resources. Human actions, according to researchers and specialists, are contributing to global warming. The fact of economic catastrophe as a result of people’s abnormal engagement with the environment has just lately become increasingly evident. The construction industry does have a certain percentage of participation. Buildings are estimated to generate up to one-third of the world’s total greenhouse gas pollution, owing largely to the usage of fossil fuels throughout their operating period (Huovila, Ala-Juusela, Melchert, & Pouffary, 2009). Enormous carbon emissions pose a serious danger to the planet and might lead to severe issues in the future. Buildings alone account for around 37% of CO2 emissions in North America and 40% in Europe, and this trend is expected to persist in the coming years (Beyer, 2012). Furthermore, if we maintain to construct using unsustainable resources, we will ultimately run out of resources to construct with. The planet is quickly nearing a peak when it will run out of resources and energy. This cause-and-effect relationship will not just harm the present generation, but all subsequent generations will have to cope with the issues that have been generated. Moreover, if the intended objectives for constructing sustainably and environmentally friendly are to be fulfilled, the building industry must take pollutants from the building sector considerably more seriously.

According to Aciu (2014), the whole lifespan of a building has an influence on the environment. This is evaluated using a technical tool known as Life Cycle Assessment (LCA) or the cradle-to-grave method. LCA is a type of evaluation in which the materials, construction, usage, and destruction of a structure are evaluated into embodied energy and CO2 equivalents, as well as visualizations of resource utilization and emitted pollutants. These insights are valuable for architects, structural engineers, constructors, and building owners who want to estimate environmental consequences during the lifespan of a project.

Steel and concrete, for instance, take a considerable amount of energy to manufacture, transport and install, although accounting for a small portion of the overall cost of the construction. Embodied Energy (EE) is the energy utilized by all operations, as per professionals (Høibø et al, 2015). When the little quantity of embodied energy (carbon) in one tonne of concrete is amplified by the massive proportion of concrete utilised, concrete becomes the substance with the most carbon throughout the world. Concrete has the greatest EE at 12.5MJ/kg EE, followed by steel at 10.5MJ/kg EE and wood at 2.00MJ/kg EE Hsu 2010). The embodied energy level of each building material varies widely, particularly concrete, since cement manufacturing is indeed very energy and fossil-fuel demanding, making it a top generator of CO2 emissions that adds to global warming (Shams et al, 2011).

When the Embodied Energy of concrete and steel is considered, it is concluded that their environmental consequences are quite severe. Wood structures, on the other hand, use less energy from resource extraction through production, distribution, usage, and end-of-life disposal, and are responsible for considerably fewer greenhouse gas emissions, air pollution, and water pollution. (Shams et al. 2011) contrasted El Dorado High School in Arkansas, which was constructed of wood, against comparable structures constructed of steel or concrete. The authors determined that the ecological design and construction of a wood structure also referred to as a green building, comprises about 153,140 cubic feet of timber, panels, and engineered wood, which is equivalent to taking 2,184 cars off the road for like a year. For this mass of wood, the ASTF (Alliance for Saving Forests) estimates that forests can grow this much wood every 13 minutes, with the carbon trapped in the wood amounting to roughly 3,660 metric tonnes of CO2 and the averted greenhouse gas emissions amounting to 7,780 metric tonnes of CO2. This demonstrates that wood is the most recyclable, biodegradable, non-toxic, and energy-efficient construction material accessible. In response, governments and industry in timber-rich countries such as Austria and Scandinavia have given the wood a practical boost, and the US Department of Agriculture lately initiated a contest for wooden high-rise designs and revealed a $1 million investment to train architects and builders to work with wood (Humphries, 2015).

When discussing aspects that emphasize sustainability, professionals frequently take the manufacturing of construction material into consideration. This factor is evaluated using the LCA. Some construction materials, such as steel, are more complex to produce, and because they are basically non-renewable, they add more to overall material usage (Kim et al, 1998). Furthermore, the risks of its manufacturing were unheard of at the time. Temperatures of up to 3,500 degrees Fahrenheit are essential for the manufacturing of steel, cement, and glass, which is accomplished using massive amounts of fossil fuel-based energy. Wood, on the other hand, is created utilizing solar energy (Shams, Mahmud, & Amin 2011). In office and commercial buildings, switching from unsustainable construction materials like concrete and steel to sustainable building materials like wood may significantly assist decrease the negative effect of construction on the environment.

In terms of building material manufacturing, timber has a significant ecological advantage over steel and concrete. Wood is a completely natural substance that can regenerate and reproduce. Trees, like any other crop, may be harvested and readily converted into a framework. Tree farms can be used to bulk produce structural material. They have the potential to be productive and sustainable, but they are not compelled to follow any type of sustainability rules. This is disappointing, but by implementing new laws, we can create the most viable material even more sustainable. We can make certification by the American Tree Farm System a legal requirement. There are no longer arguments for why wood is not the most sustainable material if it is necessary (Standards for Certification, 2016).

There are eight conditions that must be met in order to get certified by the American Tree Farm System. The first criteria is a dedication to sustainable forestry practices. Tree farmers can help by creating a forest management plan and following sustainable techniques. The second criteria are adherence to the law. This criterion merely requires the landowners to adhere to all applicable rules. The third criteria are landowner reforestation and afforestation. The fourth criterion is known as air, water, and soil protection. This criterion is long-term since it demands the landowner to sustain or improve the condition of the land. The fifth criterion is the health of your forests and the creatures that live there. Forest aesthetics is the sixth criterion. The seventh priority is to safeguard unique locations. Historical, archaeological, cultural, geological, biological, or ecological features are required for special locations. The last criterion, standard eight, involves the harvesting of forest products and associated activities. All of the requirements demonstrate to the public that even when these tree farms are utilised for commercial reasons, they contribute to the ecological health of the environment. The farms will have a constant presence of possibly 50 to 80 years. That duration establishes a consistent revenue and, as a result, protects the region from additional expansion. A forest that generates revenue will benefit the planet far more than a power plant that makes money. This balance of industrialization and forest health results in a very sustainable economy.

The breakdown of building material is the second most significant aspect of its energy cost. If a material cannot be effectively reused, it is not sustainable. When we break down concrete, it can never be utilized again for building. Steel needs a tremendous amount of energy to heat up and melt into a new substance. When steel is recycled, it must be melted at high temperatures in order to be transformed into fresh material. The energy expected to recycle steel is derived from fossil fuels. Reusing steel is still hazardous to the planet. Wood is a material that may readily be utilized for building and takes minimal energy to reclaim. If the wood has not rotted, reclaimed wood, the term used for extracted lumber from ancient constructions, can be retrieved underwater. [BJ1] One advantage of utilizing salvaged wood instead of fresh new wood is that we may utilise larger pieces of timber while new wood cannot grow as tall owing to time constraints. When new wood begins to dry out, it also requires time to shrink into its size. Reclaimed wood, on the other hand, maybe considerably more trustworthy than new wood as long as it has not rotted (Erhlich, 2011).

Reclaimed wood not only decreases the carbon impact of building, but it is also more cost-effective than purchasing new wood, which requires money to produce and grow. The market for recycled construction materials is less expensive than the market for new building materials. People have been able to establish their own professions and a new market by using reclaimed wood. People look for firms that take wood and contact them in order to dispose of the materials (Martin, E., & Schendel, E., 2014). Every day, new structures are being built and old buildings are being demolished. As a result, individuals are constantly looking for ways to get rid of outdated materials like wood. Although not all of the materials can be recovered, a little goes a long way. (Martin, E., & E. Schendel, 2014) Having the possibility of reusing and recycling materials on a regular basis generates a long-lasting cycle. Fewer trees are required, landfills will not be filled with perfectly recyclable timber, and the customer will save money since labor costs will be considerably lower.

Despite the fact that wood offers greater environmental benefits than other materials, it is not used as much as it should be. At the moment, though, some people are striving to move green buildings ahead. LEED, or Leadership in Energy and Environmental Design, was created in March 2000 by the non-profit U.S. Green Building Council (USGBC). This implies that in order to get LEED certified, a builder must be environmentally conscious and efficient with resources. They have used their standards on over 83 thousand projects throughout the world. (LEED, 2016)

One requirement for LEED certification is that the construction has a low embodied energy. The entire quantity of energy required to transport items to the worksite is referred to as embodied energy. When it comes to wood, this includes the gas used to power chainsaws, transportation to the mill/job site, and the energy used to cut the timber and transform it into building material. To be LEED-certified, you must consider how far away the source is. If the expense of wood is lower at a source 100 miles away than at a supplier 10 miles away, LEED will still demand you to choose the nearest one in order to save embodied energy (LEED, 2016). The LEED rating system successfully encourages green building and the development of sustainable infrastructure.

The research and illustrations throughout the paper demonstrate that wood is, in the end, the most sustainable building material. Wood is a recyclable and environmentally friendly building material. Forest farms may be able to assist combat the rising deforestation problem. Society must transition from mostly using concrete and steel to primarily using wood. To accomplish this, the government should create subsidies for the use of sustainable materials. Nothing will get done unless explicit regulations are established and contractors are paid for satisfying sustainability criteria. Certifications and tax breaks are examples of incentives. The fundamental objective is to reduce the cost of sustainability while increasing the cost of unsustainability. Simply by instituting positive incentives for the use of wood, society might maintain a long heritage of utilizing wood as the most prevalent construction material.

A certification offers significant benefits for sustainable building. Attaching a LEED certification to a building’s resumé makes it a wonderful marketing tool. Contractors might discover new clients thanks to these accolades. The reality that they are green buildings distinguishes them from the general pool of development, making them an investment worthwhile. According to Vierra’s (2014) research, the sustainable building attracts more investors, saves a lot of money by reducing the amount of energy used in its construction, and even comes with tax breaks. Return on investment for sustainable buildings has been found to improve by up to 6.6%. In addition, certified construction has experienced a 3.5% rise in occupancy and a 3% spike in rent (Vierra, 2014). Construction is a business, and businesses rely on revenue. Obtaining certification improves the number of customers and hence the amount of money, and this alone should be a key motivator for more builders to construct sustainably.

In the U.S., federal tax credits are available for business structures constructed with low-energy materials. Multiple tax credits are offered to the contractor and buyer as long as the structure is judged energy efficient. One of the most effective methods to alter a practice is to incentivize green building with the promise of lower costs. Vierra (2014) The Business Income Tax Deduction, for instance, is included in the Energy Policy Act of 2005. If the company uses energy-efficient equipment or materials, the tax credit might be worth up to $1.80 per square foot (DiPeso, 2007). In the long term, this may save corporations a lot of money. The most effective method to reform the construction sector is to develop a system that eventually eliminates unsustainable building materials. Construction can start to move towards a future of pure sustainability by introducing more tax subsidies and standards for green building.

The unsustainable building has a detrimental influence on the environment; nevertheless, transitioning from non-sustainable building materials such as concrete and steel to sustainable building materials such as wood in office and commercial buildings pushes the construction sector toward a healthier planet. Earlier, concrete and steel were the most inventive construction materials. Big grey structures were the hallmark of civilization and development throughout industrialization and continue to be so now. According to the research, this is no longer the case. These advantages have prompted the creation of programs like LEED and ATFS. They are an excellent starting point for achieving sustainability. They lay the groundwork and establish the paradigm for green building and management. LEED and ATFS are essential stepping stones, but further certifications and better rewards are required. Green construction is promoted as a feature of modern infrastructure, although it is not the most often utilised approach. With greater incentives, the status quo of construction can begin to advance.